APPLICATION METHOD

1. Surface Preparation

- Clean the wood surface, substrate or mold that will be poured with Propan Epoxy Cast so that it is clean of oil, dirt, mold, or other contaminants.

- Sand the wood using sandpaper.

2. Mixing Propan Epoxy Cast

- Mixing component A and component B with a ratio of A : B = 2 : 1.

- Stir thoroughly.

- Let the mixture stand for 2-5 minutes so that the air bubbles in the mixture can break.

- Then pour this mixture into the mold or substrate container that you want to cast.

- Immediately do the casting after component A and component B are stirred evenly. The mixtures will thicken (reach pot life) after 25 minutes. Then the casting process must be done before reaching potlife.

3. Drying Time (at room temperature 30°C)

Dry surface : 3 hours

Hard dry : 8 hours

Perfect dry : 7 days

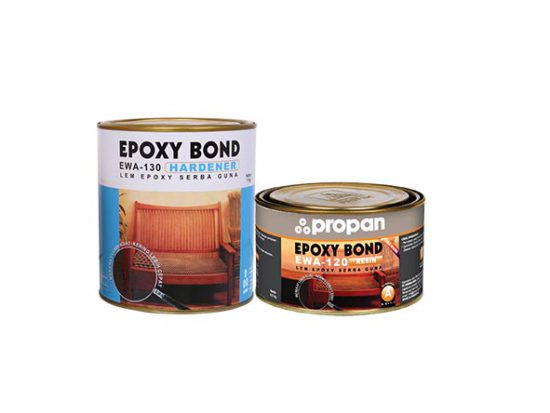

| PROPAN EPOXY CAST EC-973 | |

| Type | Two Component Epoxy |

| Colors | Clear (Transparant) |

| Application Condition | 25 – 30°C, 40 – 60% RH |

| Mixing ratio | 2 : 1 |

| Material Consumption | 0.42 kg/m?2; for 0,1 mm |

| Drying Time | 7 days |

| Hardener | ECH-973 PS |

| Pot Life | 25 minutes (30°C) |